W11S Upper Roller Universal Plate Rolling Machine

Model:W11S

Controller:PLC

Capabilities:6-300mm

- Description

Main Features

- Compact appearance design facilitates the transportation of medium and large machines.

- Horizontal movement of two lower rollers, lower working height requires smaller foundation pit and smaller foundation bolt load (minimum machine doesn’t need foundation).

- During the pre-bending and rolling, the plates always keep in a horizontal position so that the material can be moved more easily.

- Solid and special geometry structure makes it more suitable for use.

- Small lower roller center distance is conducive to the prebending of thin-plate with small diameter, which can meet the pre-bending of various diameters.

- Another important feature of 3R UHS rolling machine is the operation of the lower roller, in fact, the upper roller can be used as a traditional bending machine, which can achieve the cylinder alignment, in the same way, the thick plate cone can be made through several times rolling.

- Some 3-roller and 4-roller slant rolling machine must roll up one end of the upper roller to unload the finished workpiece, but the 3R UHS rolling machine do not need this, and the workpiece unloading is easier after completion.

- Large working stroke is good to get better plating rolling effect and can roll thicker plates than similar 3-roller or 4-roller plate rolling machines. Induction hardening forged rollers or SAE1050 rolling steel rollers.

- Double-speed working system.

- Conical bending device.

Main Structure

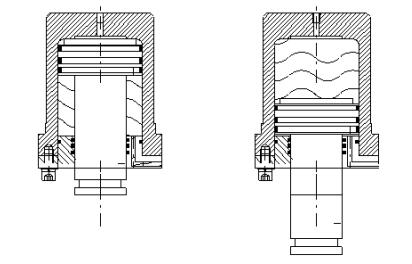

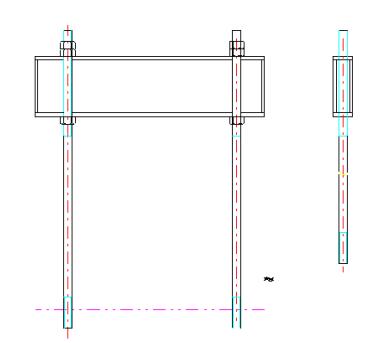

The main structure of the machine is composed of the upper roller device, the upper roller lifting device, the lower roller device, the upper roller horizontal moving device, the supporting roller device, the main driving device and the left and right side frame, the bottom basin and the balance device. The upper roller device is composed of main oil cylinder, upper roller bearing seat, upper roller and double row adjustable center bearing. The main oil cylinder and piston rod are all 45# forgings, the inner surface of cylinder is calenderized, and the piston rod is plated with Cr. The sealing element adopts Yx type sealing ring imported from Japan, which provides the pressure needed for rolling plate by rodless cavity. The piston rod of the main cylinder is connected with the bearing seat of the upper roller. As shown in the figure:

3-1. The upper roller is designed to be drum shaped

Generally, the load coefficient of the upper roller pressure is 0.7.The roller hardness processing steps can be divided into two steps, the tempering and hardening hardness is HB240-280 and surface medium frequency quenching HRC45-52, as shown in the figure:

The two ends of upper roller are equipped with double row center-adjustable bearing Double row and double row aligning bearings are arranged in upper roller bearing seats at both ends (Wafangdian

bearing), as shown in the figure:

3-2 Upper roller lifting device

The upper roller is driven by two oil cylinders, with the highest working pressure of 19.5mpa. The upper roller is equipped with rolling bearings at both ends, and the bearing seat moves up and down along the guide rail. The bearing seat at both ends is equipped with displacement sensors to display the movement amount and readout in digital display

meter.

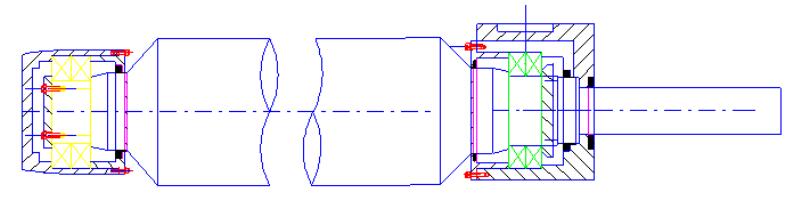

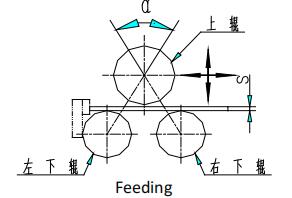

3-3 Lower roller device and horizontal moving device

Lower roller device is formed by the lower roller, bearing seat, input gear, sliding bearing and so on, through the main transmission output gear lower roller input gear open drive lower roller torque to the lower roller. As shown in the figure:

Horizontal moving device is driven by the transmission motor through worm gear box, worm gear and worm screw mechanism to realize asymmetric rolling. Moving position is displayed in digital display meter.

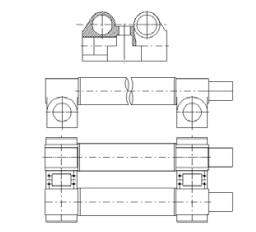

3-4. Idler device

Idler device is composed of screw mechanism, inclined wedge mechanism and idler. Roller is made of 45 # steel, the tempering hardness HB190-220, the surface hardness of idler is lower than that of lower roller, and the idler surface with spiral groove prevent welding slag, oxide skin, mixed skin etc damaging work rollers, and the idler roller can be adjusted up and down according to plate size and load. As shown in the figure:

3-5 Main transmission device

The main transmission device is composed of main motor and speed reducer. The main transmission can turn in both directions to provide power for rolling plate.

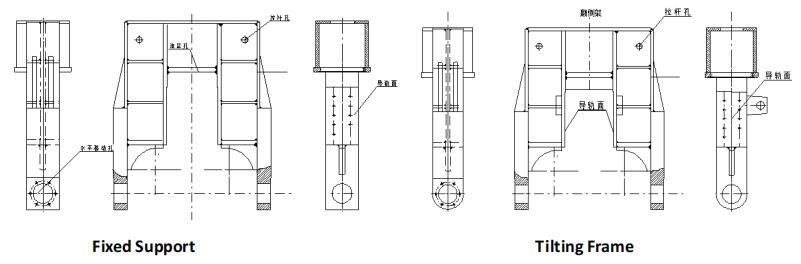

3-6 Tilting device

The tilting device is composed of frame, sliding pillow, oil cylinder and pin shaft. Tilting cylinder adopts single stage cylinder and chromium-plated piston rod. The tilting device is used to overturn the side frame, which is convenient for taking out the workpiece. After the frame is repositioned, the next workpiece can be rolled and processed. The cylinder power comes from the hydraulic power station.

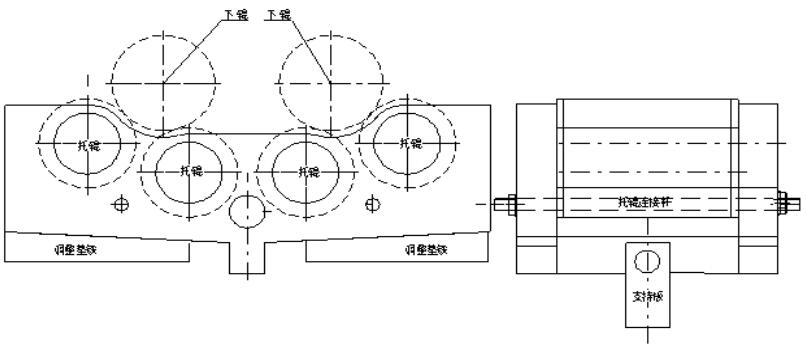

3-7 Upper roller balancing device

Lift the upper roller to a high position and hold it down by the tail of the upper roller. In this way, the upper roller is held down by bearing seat and balance beam to make the upper roller in a balanced state, which is convenient to tip over and close the bearing seat. When the upper roller rises to the highest position, it can be detected by the travel switch. As is shown in the figure:

3-8 Left and right side rack and chassis

Frame and chassis adopt frame structure, overall structure, high rigidity, as shown in following figure:

Rolling Technology

Many kinds of rolling technology are available for user to choice; here is one for your reference:

| No. | Diagram | Description |

| 1 |  |

Lifting the upper roller makes the distance between its lower busbar and the upper busbar of lower roller slightly larger than the plate thickness, and then feed the steel plate horizontally until the end of the plate in full contact with the baffle on the side of the working roller for alignment. |

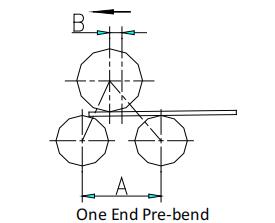

| 2 |  |

Adjusting the B distance according rolling requirement by moving the upper roller, operate the lower roller to make inching and rotate to pre-bend the end of the plate according to workpiece the curvature, the length of plate clamped by upper roller and lower left roller is 1.5-2.5 times than plate thickness; During pre-bending, the oil cylinder pressure can be adjusted to 5-20Mpa from different plate thickness. |

| 3 |  |

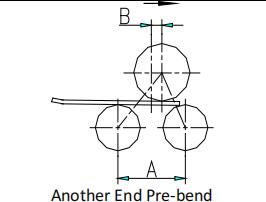

Change roller position, pre-bend the other end. |

| 4 |  |

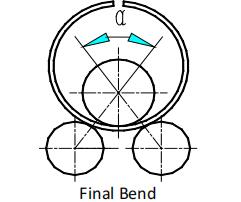

Final bend can be divided into several times, generally 4 ~ 5 times, control the upper roller down to the plate middle for the initial bending, control the lower roller rotation to make the direction of rotation consistent with the plate feed direction. |

Standard Accessories

- Linear guides for roll movement (RGS)

- 4 independent bearings supporting the lower rolls (MCS)

- Bearing seats with double width (WHS)

- Electronic synchronisation of roll parallelism (EPS)

- Induction hardened and polished rolls

- Digital readouts for roll position

- 3 independent motor-driven rolls

- Mobile wheel mounted control console

- Conical device

- Centralised manual lubrication (pump)

- Emergency barrier around the machine

- CE certified machine

OMRON PLC Controller

- TP765 color display

- Preset the displacement values of each roller

- Setting each coordinate point

- Detection of upper roller position

- Tilting frame reset

- Control the main roller rotation direction

- Control material-presser up and down

- Control the left and right rollers up and down

Standard Configuration

Overall Welding

Machine stronger welding structure , high precision and more peacefully color design and comfortable usage Referring to man-machine engineering design.

42CrMo Alloy Steel Work Roller

- Upper roller likes drum with collaboration of carrier roller permit continual bending of any thickness of plate

- Bottom roller and lateral roller driven by hydraulic oil tank

Drop-End

Standard Hydraulic Drop-End

Controller System

Omron PLC CNC control system, touch screen control, mobile console, single-person operation, efficient, safe and convenient

UNIVERSIAL PLATE ROLLING MACHINE

- The upper roller universal plate bending machine adopts the upper roller lifting hydraulic drive and horizontal movement (mechanical transmission), driven by the lower roller, and the electric centralized control operating system. It can complete the pre-bending of the two ends of the plate and the rolling barrel and arc at one time. Shape the work of the workpiece.

- It can also carry out certain shaping and leveling of the metal sheet, which has the effects of direct pre-bending, saving trouble and saving materials, and is equipped with NC system control to improve the degree of automation.

Technical Parameter

| Model | Pressure of Top Roller (T) |

Max. Bending Thickness (mm) |

Pre-bending Thickness (mm) |

Max. Bending Width (mm) |

Top Roller Diameter (mm) |

Bottom Roller Diameter (mm) |

Central Distance (mm) |

Main Motor(Kw) Drive,Hydraulic,Movement |

||

| W11S-4x2500 | 25 | 4 | 3.5 | 2500 | 200 | 125 | 160 | 4 | 2.2 | 1.1 |

| W11S-6x2500 | 30 | 6 | 5 | 2500 | 210 | 125 | 160 | 4 | 2.2 | 1.1 |

| W11S-8x2000 | 37 | 8 | 6.5 | 2000 | 210 | 135 | 180 | 4 | 2.2 | 1.1 |

| W11S-8x2500 | 37 | 8 | 6.5 | 2500 | 235 | 135 | 180 | 5.5 | 2.2 | 1.1 |

| W11S-10x2000 | 37 | 10 | 8 | 2000 | 235 | 135 | 180 | 5.5 | 2.2 | 1.1 |

| W11S-10x2500 | 55 | 10 | 8 | 2500 | 250 | 145 | 200 | 7.5 | 4 | 1.1 |

| W11S-12x2000 | 65 | 12 | 10 | 2000 | 250 | 145 | 200 | 7.5 | 4 | 1.1 |

| W11S-12x2500 | 75 | 12 | 10 | 2500 | 265 | 145 | 200 | 7.5 | 4 | 1.5 |

| W11S-12x3000 | 75 | 12 | 10 | 3000 | 290 | 150 | 245 | 11 | 4 | 1.5 |

| W11S-16x2000 | 75 | 16 | 13 | 2000 | 265 | 150 | 245 | 7.5 | 4 | 1.5 |

| W11S-16x2500 | 100 | 16 | 13 | 2500 | 300 | 165 | 270 | 15 | 5.5 | 1.5 |

| W11S-16x3000 | 130 | 16 | 13 | 3000 | 330 | 180 | 300 | 15 | 5.5 | 2.2 |

| W11S-20x2000 | 100 | 20 | 16 | 2000 | 300 | 165 | 270 | 15 | 5.5 | 1.5 |

| W11S-20x2500 | 130 | 20 | 16 | 2500 | 330 | 180 | 300 | 15 | 5.5 | 2.2 |

| W11S-20x3000 | 160 | 20 | 16 | 3000 | 380 | 200 | 330 | 18.5 | 7.5 | 2.2 |

| W11S-20x4000 | 230 | 20 | 16 | 4000 | 440 | 235 | 380 | 30 | 11 | 4 |

| W11S-25x2500 | 190 | 25 | 20 | 2500 | 380 | 220 | 360 | 22 | 7.5 | 4 |

| W11S-25x3000 | 230 | 25 | 20 | 3000 | 410 | 235 | 380 | 30 | 11 | 4 |

| W11S-25x4000 | 270 | 25 | 20 | 4000 | 490 | 250 | 400 | 30 | 11 | 4 |

| W11S-30x2500 | 230 | 30 | 25 | 2500 | 410 | 235 | 380 | 30 | 11 | 4 |

| W11S-30x3000 | 270 | 30 | 25 | 3000 | 450 | 250 | 400 | 30 | 11 | 4 |

| W11S-30x4000 | 380 | 30 | 25 | 4000 | 550 | 275 | 460 | 45 | 22 | 5.5 |

| W11S-35x2500 | 320 | 35 | 28 | 2500 | 450 | 250 | 400 | 30 | 11 | 4 |

| W11S-35x3000 | 380 | 35 | 28 | 3000 | 510 | 275 | 460 | 45 | 22 | 5.5 |

| W11S-40x2500 | 380 | 40 | 32 | 2500 | 500 | 275 | 460 | 45 | 22 | 5.6 |

| W11S-40x3000 | 430 | 40 | 32 | 3000 | 540 | 290 | 500 | 55 | 22 | 7.5 |

| W11S-40x4000 | 540 | 40 | 32 | 4000 | 630 | 340 | 610 | 55 | 22 | 11 |

| W11S-45x3000 | 540 | 45 | 36 | 3000 | 590 | 340 | 610 | 55 | 22 | 11 |

| W11S-50x2500 | 430 | 50 | 40 | 2500 | 580 | 290 | 500 | 55 | 22 | 7.5 |

| W11S-50x3000 | 540 | 50 | 40 | 3000 | 600 | 340 | 610 | 55 | 22 | 11 |

| W11S-50x4000 | 690 | 50 | 40 | 4000 | 700 | 380 | 700 | 75 | 30 | 15 |

| W11S-55x3000 | 610 | 55 | 45 | 3000 | 620 | 360 | 650 | 75 | 30 | 15 |

| W11S-55x4000 | 850 | 55 | 45 | 4000 | 750 | 420 | 780 | 90 | 37 | 15 |

| W11S-60x3000 | 690 | 60 | 50 | 3000 | 650 | 380 | 700 | 75 | 30 | 15 |

| W11S-60x4000 | 930 | 60 | 50 | 4000 | 780 | 440 | 820 | 90 | 37 | 15 |

| W11S-70x3000 | 850 | 70 | 56 | 3000 | 710 | 420 | 780 | 75 | 37 | 15 |

| W11S-70x4000 | 1150 | 70 | 56 | 4000 | 840 | 480 | 920 | 110 | 45 | 18.5 |

| W11S-75x3000 | 930 | 75 | 60 | 3000 | 740 | 440 | 820 | 90 | 37 | 15 |

| W11S-80x3000 | 1050 | 80 | 65 | 3000 | 770 | 460 | 880 | 90 | 37 | 18.5 |

| W11S-90x3000 | 1150 | 90 | 75 | 3000 | 820 | 480 | 920 | 110 | 45 | 18.5 |

| W11S-100x3000 | 1350 | 100 | 80 | 3000 | 860 | 480 | 920 | 110 | 45 | 22 |

| W11S-110x4000 | 1800 | 110 | 90 | 4000 | 950 | 600 | 1120 | 132 | 55 | 37 |

| W11S-120x3000 | 1800 | 120 | 100 | 3000 | 920 | 580 | 1120 | 132 | 55 | 37 |

| W11S-120x4000 | 2300 | 120 | 100 | 4000 | 990 | 640 | 1280 | 275 | 75 | 37 |

| W11S-150x3000 | 2300 | 150 | 120 | 3000 | 1050 | 660 | 1280 | 2x75 | 75 | 45 |

| W11S-160x3000 | 2500 | 160 | 130 | 3000 | 1080 | 700 | 1360 | 2x75 | 75 | 45 |

| W11S-160x4000 | 2800 | 160 | 130 | 4000 | 1260 | 720 | 1380 | 2x90 | 90 | 45 |