CNC Press Brake

Model:MB8 Series

Controller:DELEM DA53T

Capabilities:40T/2200-3000Ton/12000

Standard axis:Y1,Y2,X+W(Crowning)

- Description

Main Features

- Brand-new industry design combined with modern aesthetic concept, high-quality production technology, simpleappearance.

- Latest high-frequency responding hydraulic control technology, faster, more efficient and accurate.

- Heat treatment of the rack, rigidity optimization verification on entire machine and the application of hydraulic crowning structure jointly ensure the bending precision of MB8 series Press Brakes.

- Optimal ratio of parameters and core configuration ensure stable performance, and easy operation.

- DA53T controller is equipped with standard 4+1 axis (Y1, Y2,R, X axis and W axis crowning). At the same time, suitable die can be selected to realize bending processing of various workpieces with complex shapes.

- The Press Brake adopts full closed-loop electro-hydraulic servo synchronous control technology.

- CNC controller will automatically control the deflection compensation of the worktable, in order to achieve uniform angle on full length of the workpiece according to machine process state.

- Using hydraulic crowning method or mechanical crowning method, the workpiece with uniform precision over the whole length of the worktable can be obtained.

Main Accessories

- Netherlands DELEM DA53T CNC controller

- Grating ruler controls depth Y1 and Y2 axis(y1/y2-axis 0.01mm)

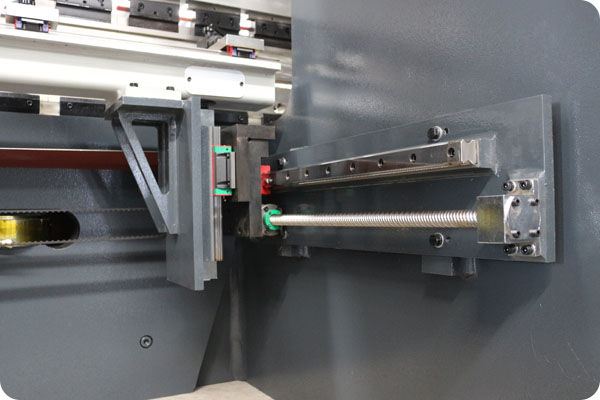

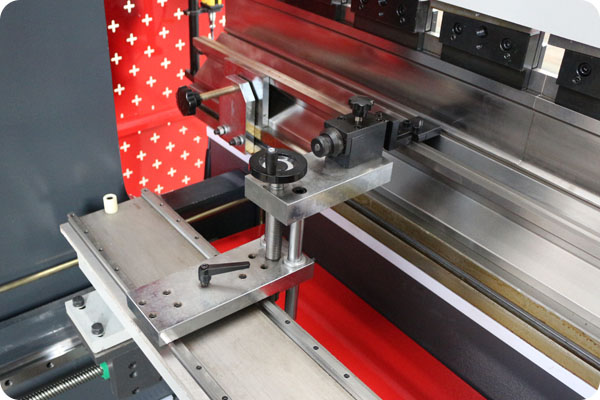

- Servo motor drive and control X axis and R axis(X/R-axis 0.01mm), manually adjusts R axis up and down, fingers can easily move along the cylindrical guide

- HIWIN ball screw and linear guide precision 0.01mm

- Front carrier can be adjusted along the linear guide in the worktable direction

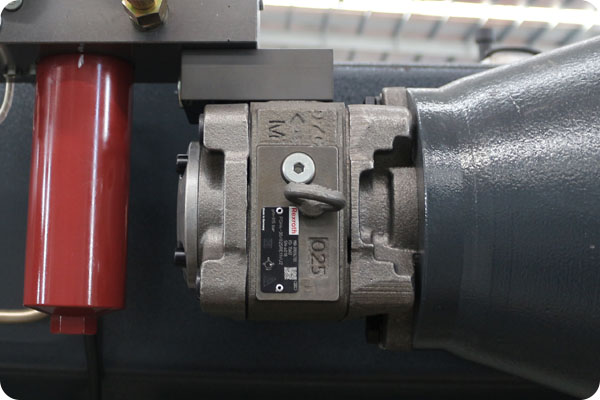

- Germany Rexroth closed-loop electro-hydraulic servo synchronous control system

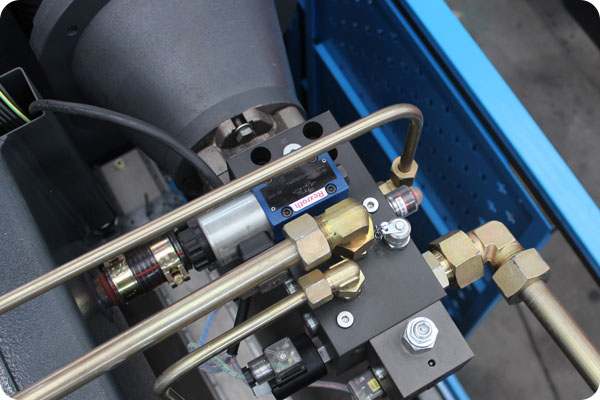

- Germany EMB oil tube connectors

- Germany Siemens main motor

- Germany Siemens main motor

- Hydraulic and electrical overload protection

- The upper die adopts mechanical quick clamping European upper die, while the lower die adopts single V double V or 4V quick changing type or multi-v lower die

DELEM DA53T CNC Press Brake Controller

- 10.1" wide screen TFT

- LED backlight

- 1024 x 600 pixels

- Industrial grade touch screen

- Storage capacity 1 GB

- Data backup / restore via USB

- USB flash memory stick

- Integrated valve amplifier

- Power-down memorisation

- Profile-53TL offline software

Safety Standard

- EN 12622:2009 + A1:2013

- EN ISO 12100:2010

- EN 60204-1:2006+A1:2009

- Front finger protection device ( safety light curtain )

- South Korea KACON foot switch ( 4 security grade )

- Back metal safety fence, CE standard

- Safety relay monitors completed with foot switch, safety protection devices

- Safety standard(2006/42/EC)

Standard Configuration

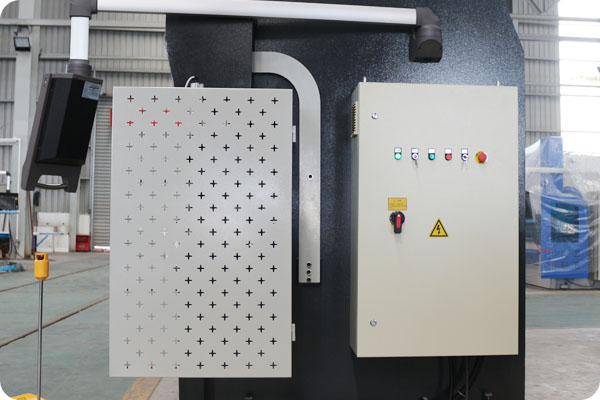

CE Standard Electrical System

Schneider Electrics - France

Siemens Motor

Bosch Rexroth Pump-Germany

Bosch Rexroth Valve -Germany

Y1,Y2 Rexroth Closed Cycle Valve

FAGOR Grating Ruler - Spain

Taiwan HIWIN Linear Guide

Manual Fine Tuning Back Stopper

Linear Guide Back Gauge Beam

KACON Foot Switch -South Korea

Infrared Point-to-point Protection

Moveable Front Support Arm

Standard Machine Crowning

EMB Oil Pipe -Germany

Snap-in Type Quick Clamps

Optional controller

DELEM DA58T CNC Press Brake Controller

- 2D graphical touch screen programming

- 15" high resolution colour TFT

- Bend sequence calculation

- Crowning control

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- USB, peripheral interfacing

- Profile-T offline software

DELEM DA66T CNC Press Brake Controller

- 2D graphical touch screen programming mode

- 17" high resolution colour TFT

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control's multitasking environment

- Sensor bending & correction interface Profile-TL offline software

DELEM DA69T CNC Press Brake Controller

- 3D and 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- 17" high resolution colour TFT

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- User specific application support within the control's multitasking environment

- Sensor bending & correction interface

- Profile-T3D offline software

Technical Parameter

| Model | Bending Pressure (Kn) | Bending Length(mm) | Column Distance (mm) | Throat Depth (mm) |

Slider Stroke (mm) |

Max. Opening Height (mm) |

X-axis Max Distance(mm) | Main Motor (Kw) |

Length* Width* Height(mm) | Weight (T) |

| 63T/2500 | 630 | 2500 | 1900 | 350 | 170 | 380 | 500 | 5.5 | 3100*1450*2050 | 5.8 |

| 100T/3200 | 1000 | 3200 | 2700 | 400 | 200 | 420 | 500 | 7.5 | 3500*1580*2400 | 8.5 |

| 110T/3200 | 1100 | 3200 | 2700 | 400 | 200 | 420 | 500 | 7.5 | 3500*1580*2400 | 8.8 |

| 125T/3200 | 1250 | 3200 | 2700 | 400 | 200 | 420 | 500 | 11 | 3500*1580*2400 | 9.5 |

| 135T/3200 | 1350 | 3200 | 2700 | 400 | 200 | 420 | 500 | 11 | 3500*1580*2400 | 9.9 |

| 160T/3200 | 1600 | 3200 | 2700 | 400 | 200 | 420 | 500 | 11 | 3500*1650*2500 | 11 |

| 175T/3200 | 1750 | 3200 | 2700 | 400 | 200 | 420 | 500 | 11 | 3500*1650*2500 | 11 |

| 200T/3200 | 2000 | 3200 | 2700 | 400 | 200 | 420 | 500 | 15 | 3500*1680*2550 | 14 |

| 250T/3200 | 2500 | 3200 | 2700 | 400 | 200 | 420 | 500 | 15 | 3500*1700*2600 | 15.5 |

| 300T/3200 | 3000 | 3200 | 2700 | 400 | 200 | 420 | 500 | 22 | 3500*1800*2730 | 16.8 |

| 400T/4000 | 4000 | 4000 | 3500 | 400 | 320 | 420 | 500 | 30 | 4500*2450*3500 | 31 |

| 500T/6000 | 5000 | 5000 | 4900 | 500 | 320 | 600 | 800 | 37 | 6500*2810*4500 | 53 |

| 600T/6000 | 6000 | 6000 | 4900 | 500 | 320 | 600 | 800 | 45 | 6500*2910*5100 | 68 |

| 800T/6000 | 8000 | 6000 | 4900 | 600 | 400 | 600 | 800 | 55 | 6500*2950*5300 | 90 |

| 800T/8000 | 8000 | 8000 | 5900 | 600 | 400 | 600 | 800 | 55 | 8500*2950*5900 | 120 |

| 1000T/6000 | 10000 | 6000 | 4900 | 600 | 400 | 600 | 800 | 2*37 | 6500*3000*5600 | 100 |

| 1000T/8000 | 10000 | 8000 | 6900 | 600 | 400 | 600 | 800 | 2*37 | 8500*3000*6100 | 130 |

| 1000T/10000 | 10000 | 10000 | 8000 | 600 | 400 | 600 | 800 | 2*37 | 10500*3000*5850 | 150 |

| 1200T/6000 | 12000 | 6000 | 4900 | 600 | 400 | 800 | 1000 | 2*37 | 6500*3100*5850 | 130 |

| 1200T/7000 | 12000 | 7000 | 5900 | 600 | 400 | 800 | 1000 | 2*37 | 8500*3100*7150 | 160 |

| 1600T/6000 | 16000 | 6000 | 4900 | 600 | 400 | 800 | 1000 | 2*55 | 6500*3300*6500 | 150 |

| 1600T/7000 | 16000 | 7000 | 5900 | 600 | 400 | 800 | 1000 | 2*55 | 7200*3300*7000 | 170 |

| 1600T/8000 | 16000 | 8000 | 6900 | 600 | 400 | 800 | 1000 | 2*55 | 8500*3300*8000 | 190 |

| 1600T/10000 | 16000 | 10000 | 8000 | 600 | 400 | 800 | 1000 | 2*55 | 10500*3300*8000 | 210 |

| 2000T/8000 | 20000 | 8000 | 6200 | 600 | 400 | 800 | 1000 | 2*55 | 8500*3500*8000 | 260 |

| 2000T/10000 | 20000 | 10000 | 8000 | 600 | 400 | 800 | 1000 | 2*55 | 10500*3500*8300 | 290 |

| 2000T/12000 | 20000 | 12000 | 9050 | 600 | 400 | 800 | 1000 | 2*55 | 12500*3500*8300 | 320 |

| 2000T/14000 | 20000 | 14000 | 11000 | 600 | 400 | 800 | 1000 | 2*55 | 14500*3500*8300 | 350 |

| 3000T/8000 | 30000 | 8000 | 6200 | 600 | 400 | 800 | 1000 | 2*55 | 8500*3700*8600 | / |

| 3000T/10000 | 30000 | 10000 | 8000 | 600 | 400 | 800 | 1000 | 2*55 | 10500*3700*8600 | / |

| 3000T/12000 | 30000 | 12000 | 9050 | 600 | 400 | 800 | 1000 | 2*55 | 12500*3700*8600 | / |

| 3000T/14000 | 30000 | 14000 | 11000 | 600 | 400 | 800 | 1000 | 2*55 | 14500*3700*8600 | / |

Working Vedio

CATEGORY AND TAGS: