Use Advantages of 3 Roll Symmetrical Plate Bending Machine and How to Adjust Roll Speed

Use Advantages of 3 Roll Symmetrical Plate Bending Machine and How to Adjust Roll Speed

There are mechanical and hydraulic three roll plate rolling machine: mechanical three roll plate rolling machine is divided into symmetrical and asymmetrical. The following is about the performance characteristics of the mechanical 3 roll symmetrical plate bending machine.

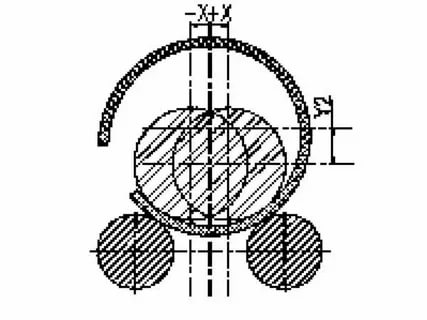

Performance characteristics of mechanical three roll symmetrical plate bending machine: the structure of the machine is three roll symmetrical, the upper roll makes vertical lifting movement in the central symmetrical position of the two lower rolls, which is obtained through the transmission of screw rod and worm, the two lower rolls make rotary movement, and mesh with the lower roll gear through the output gear of the reducer to provide torque for plate rolling. The disadvantage of mechanical three roll symmetrical plate bending machine is that the end of plate needs to be pre bent with other equipment.

The three roll plate bending machine is fully hydraulic driven. The three rolls are all active rolls. The upper roll only rotates and does not move. The two lower rolls rotate and can move in an arc at the same time. The advantages of this arc motion mode of the lower roll are: when going up, the distance between the center of the two lower rolls is close, so that the straight section of the plate is short; When descending, the descending distance is very short, and the center distance between the two rollers is very large, forming a longer arm of force, which is scientific and conducive to the application of force. The bending machine can realize the pre bending at both ends of the steel plate on the bending machine without other equipment.

Manual debugging is also very important to achieve the best function of CNC plate bending machine

1. Up: close the door in place, press and hold the up button, the cot will rise, release the up button, the cot will stop rising. Rise to the right position and check whether the upper limit photoelectric switch works normally. If not, please adjust the position and check whether it is damaged.

2. Turn on the oil pump, check the rotation direction of the oil pump motor, check the oil pressure, and check for oil leakage.

3. Motor: the door is closed in place, press and hold the motor button, the motor rotates, release the motor button, the motor stops rotating. Check whether the motor rotation direction is correct.

4. Turn the (manual / automatic) pull switch to manual.

5. Connect the 380VAC power supply to the terminals (R, s, t) of the electric box, push the circuit breaker on after correct connection, close the electric box, check the hydraulic pressure and check whether there is oil leakage.

6. Close the door: press and hold the close button, the close cylinder will work, release the close button, and the close cylinder will stop working. Close the door in place and check whether the photoelectric switch works normally. If not, please adjust the position and check whether it is damaged.

7. Descent: the door is closed in place, press and hold the descent button, the cot will descend, release the descent button, and the cot will stop descending. Lower to the position, check whether the lower limit photoelectric switch is working normally and the indicator light is on. If not, please adjust the position and check whether it is damaged.

8. Turn on the power switch and the power indicator (red) is on.