Five Maintenance Methods of 4 Roll Plate Bending Machine

Five Maintenance Methods of 4 Roll Plate Bending Machine

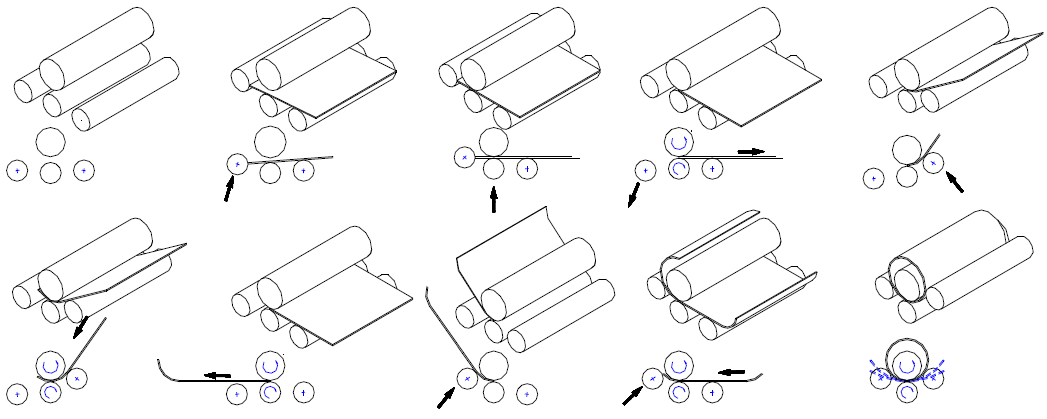

The 4 roll plate bending machine is suitable for bending and forming of metal sheet. It can roll round, arc and conical workpiece within a certain range. It has the function of pre bending at the end of the plate. The remaining straight edge is small and the working efficiency is high. It can also rough level the metal sheet on the machine.

In the process of rolling, the hydraulic cylinders at both ends of the lower roll should not only provide pressure, but also have the function of pressure maintaining. In the design, the force of the lower roll (clamping force w) is less than the force required for plastic deformation when the rolled steel plate is compressed. Today, we mainly introduce the five major maintenance methods of the lower four roll plate bending machine.

1. Look

Every day, check whether there is water leakage and dripping around the plate bending machine, which will cause low breakdown of motor insulation and burn out. Also, check whether there are objects affecting its ventilation and heat dissipation environment around it. Check whether the fan end cover, fan blade and motor are too dirty and need to be cleaned. Ensure its cooling and heat dissipation effect.

2. Measurement

when the rolling machine stops running, the insulation meter should be used to measure the resistance of each phase to ground or phase to phase. When it is found, the moisture lamp should be used to bake to improve the insulation, so as to avoid the winding breakdown and motor damage due to too low insulation.

3. Listen

listen carefully to see if the running sound of the motor is abnormal. If the rolling machine is noisy, you can use a screwdriver or a listening stick to find its vibration. You can even judge the amount of internal bearing oil, so that you can take corresponding measures such as adding bearing oil, Zhoushan four roll rolling machine, or replacing new bearings, Avoid the motor bearing oil dry grinding and locked rotor, go round, sweep bore burning.

4. Touch

Use the back of your hand to detect the temperature around the motor of the rolling machine. Under the condition of good bearing condition, the temperature at both ends will generally be lower than that of the middle winding section. If the temperature at both ends of the bearing is higher, check the bearing according to the measured bearing sound. If the overall temperature of the motor is higher, the price of the 4 roll rolling machine will be quoted, It is necessary to check the load, equipment and ventilation of the motor according to the working current.

5. What to do

Not only to take timely remedial measures for the problems found in the inspection, but also to tighten the screws and wiring of the motor according to the maintenance cycle, supply the 4 roll plate bending machine, disassembly inspection, cleaning and maintenance, etc. for the normal operation of the plate bending machine motor, the mechanic and maintenance electrician must carry out the maintenance once a year.